Do we want laminar flow or turbulent flow? This question often comes up in discussions about ultrasonic flow metering. The truth is, what we really care about is how the flow profile behaves at any given moment. Why, you ask? It all has to do with a phenomenon called the Reynolds Number.

In short, the Reynolds number is a calculation that describes the amount of turbulence in a fluid— in this case, liquid flowing through a pipe. If you’d like to dig deeper into Reynolds numbers and how they behave in a pipe, get in touch with us!

Back on track: Reynolds Number is important because, depending on the density, viscosity, and velocity of the fluid inside the pipe, the ability to accurately calculate flow can be significantly affected. Ultrasonic flowmeters use these fluid properties (typically as static values) to determine the Reynolds number and then apply a compensation value to correct for the flow profile at a given velocity.

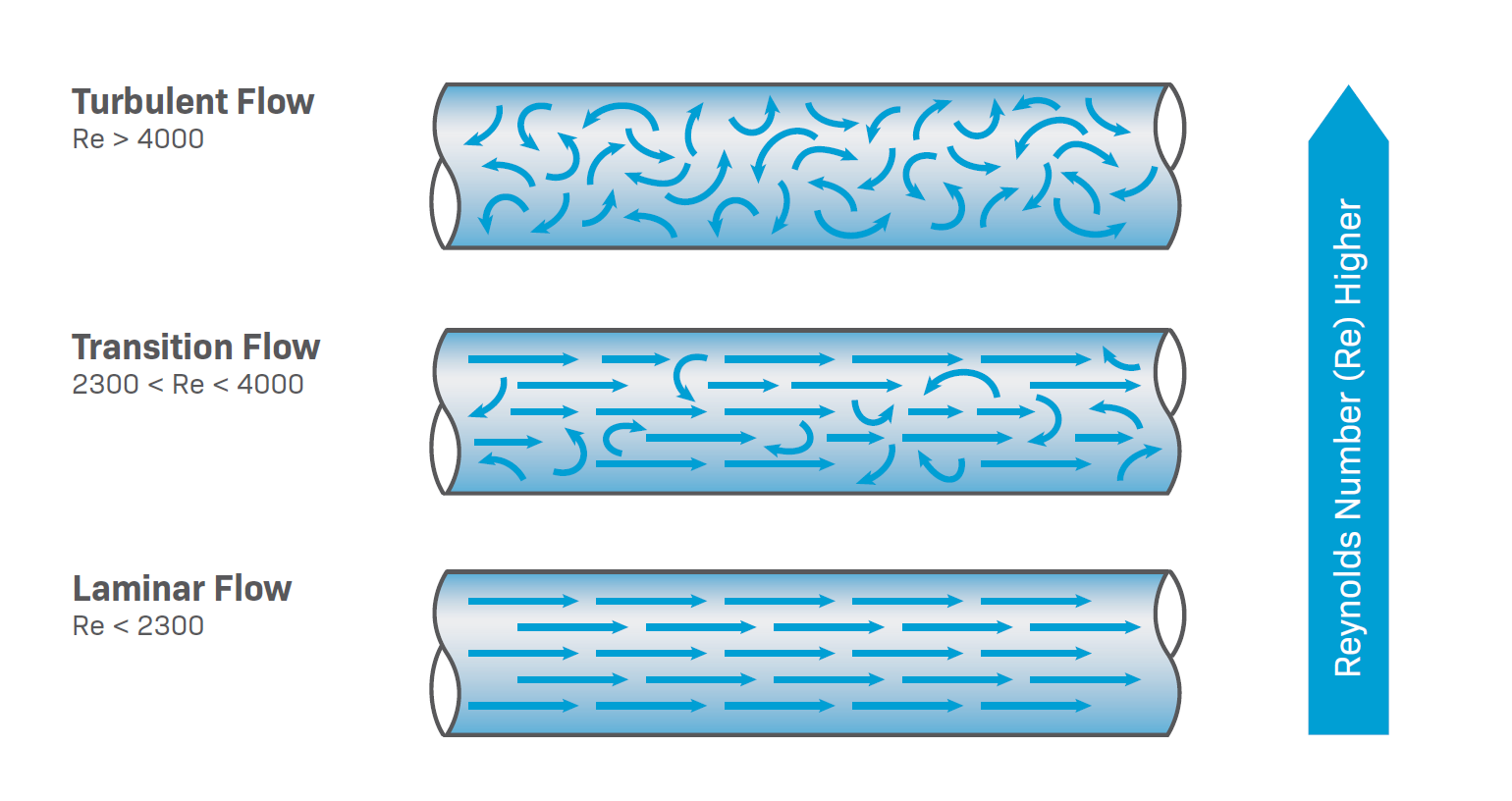

There are three main Reynolds number ranges—or “profiles”—that affect this correction factor:

Laminar = Re below approximately 2,000

Transitional = Re between approximately 2,000 and 6,000

Turbulent = Re above 6,000

Most liquids have fairly similar densities and viscosities, with their respective flow profile changes similarly occurring. Two ends of the spectrum, for better understanding, are high density/viscosity liquids, and gases. High-density and/or high-viscosity fluids have a substantial effect, in terms of velocity change, in which the Reynolds number moves from laminar to turbulent. The velocity of the liquid with those properties has to increase by many orders of magnitude to change flow profile regimes. Gases, on the other hand, shifts almost immediately to a fully turbulent flow profile regime as the velocity moves off of zero flow.

In essence, as Reynolds number increases, so does the correction factor.

Why does this matter? Because without this correction—or compensation—the calculated flow rate accuracy can be significantly affected, sometimes by several percent.

The key takeaway: when using clamp on flow measuring with a viscous fluid or a low-velocity flow in a medium-to-large pipe (8” or larger, generally speaking), your published flow measurements could potentially differ from the actual rate. Being mindful of this is important when readings differ significantly from expected values— one of the first places to look is at the velocity and what the Reynolds number is at that specific flow velocity, in given conditions. SWT’s Line of Clamp-On Ultrasonic Flowmeters have automatic Reynolds number compensation, ensuring your flow measurement readings stay accurate.

If you would like to understand this topic in more detail, or discuss your specific application, feel free to reach out at sales@soundwatertech.com, or by phone at (509) 899-7838.